Software

Software

Reliable safety programs, sophisticated PLC programs

and intuitive user interfaces - all perfectly matched.

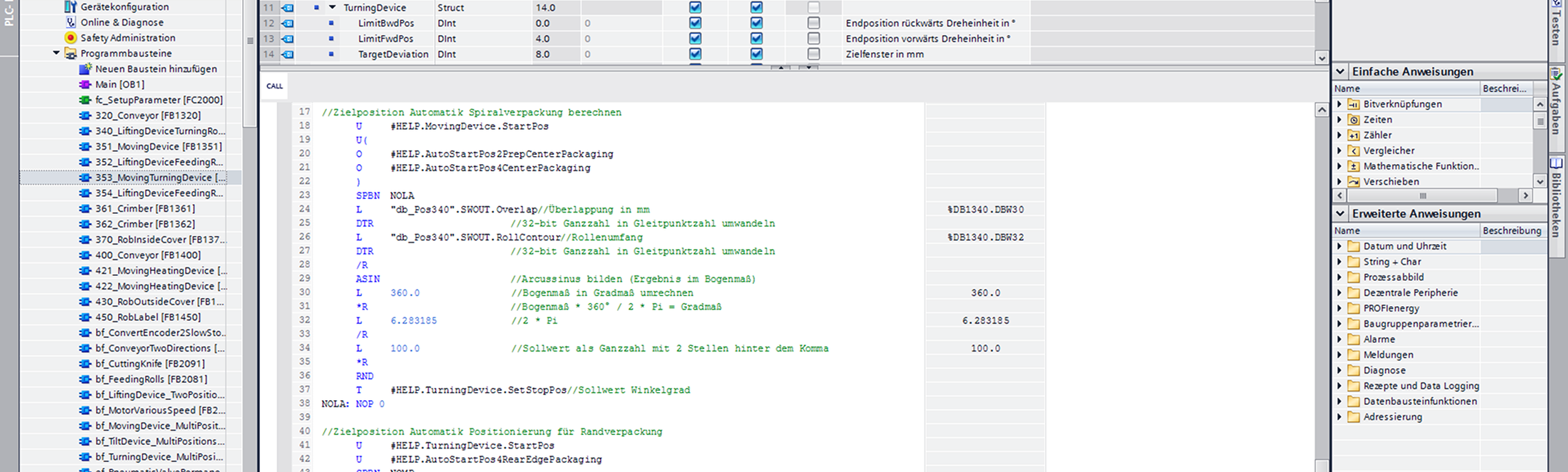

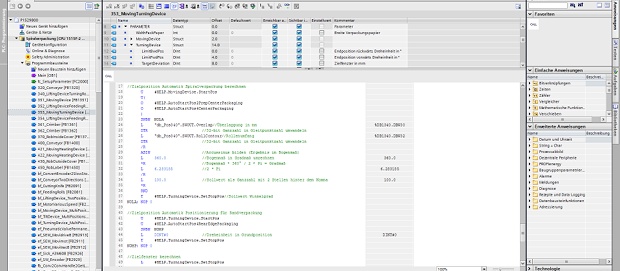

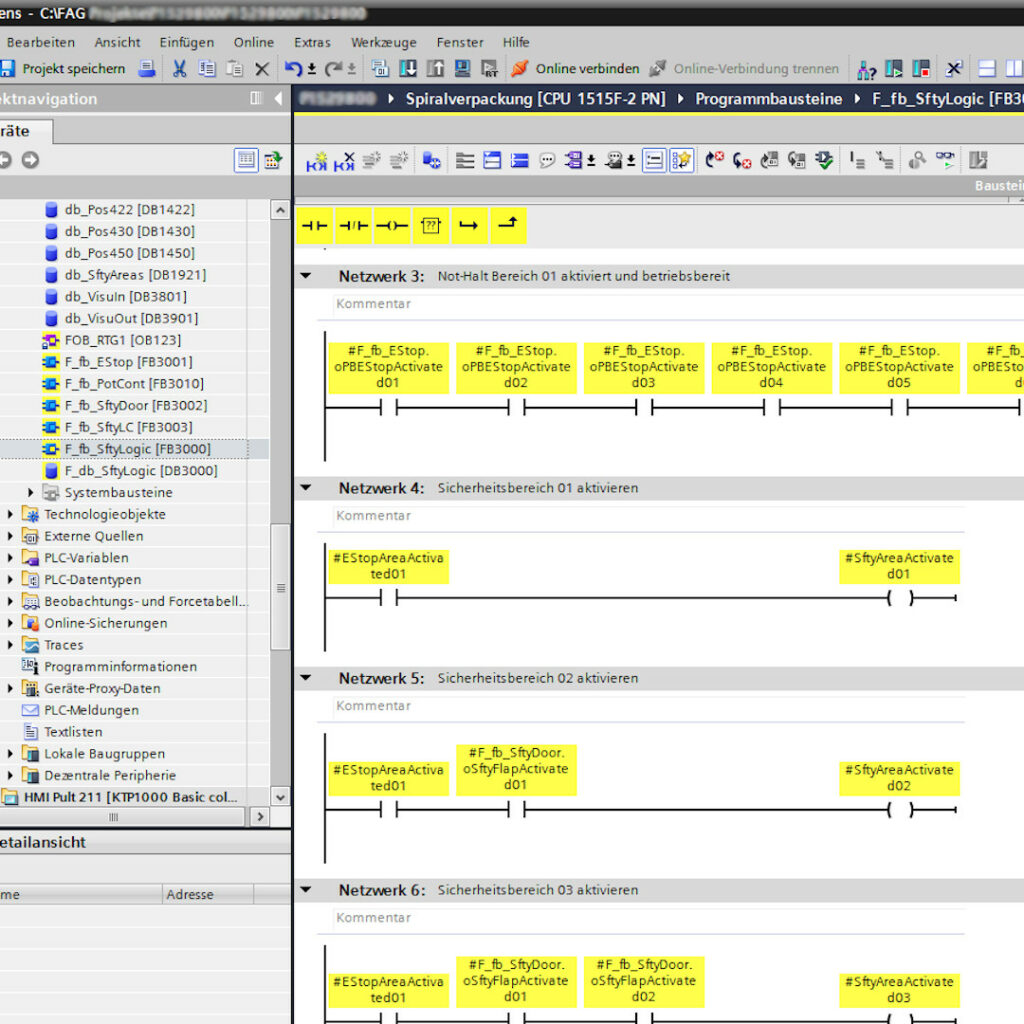

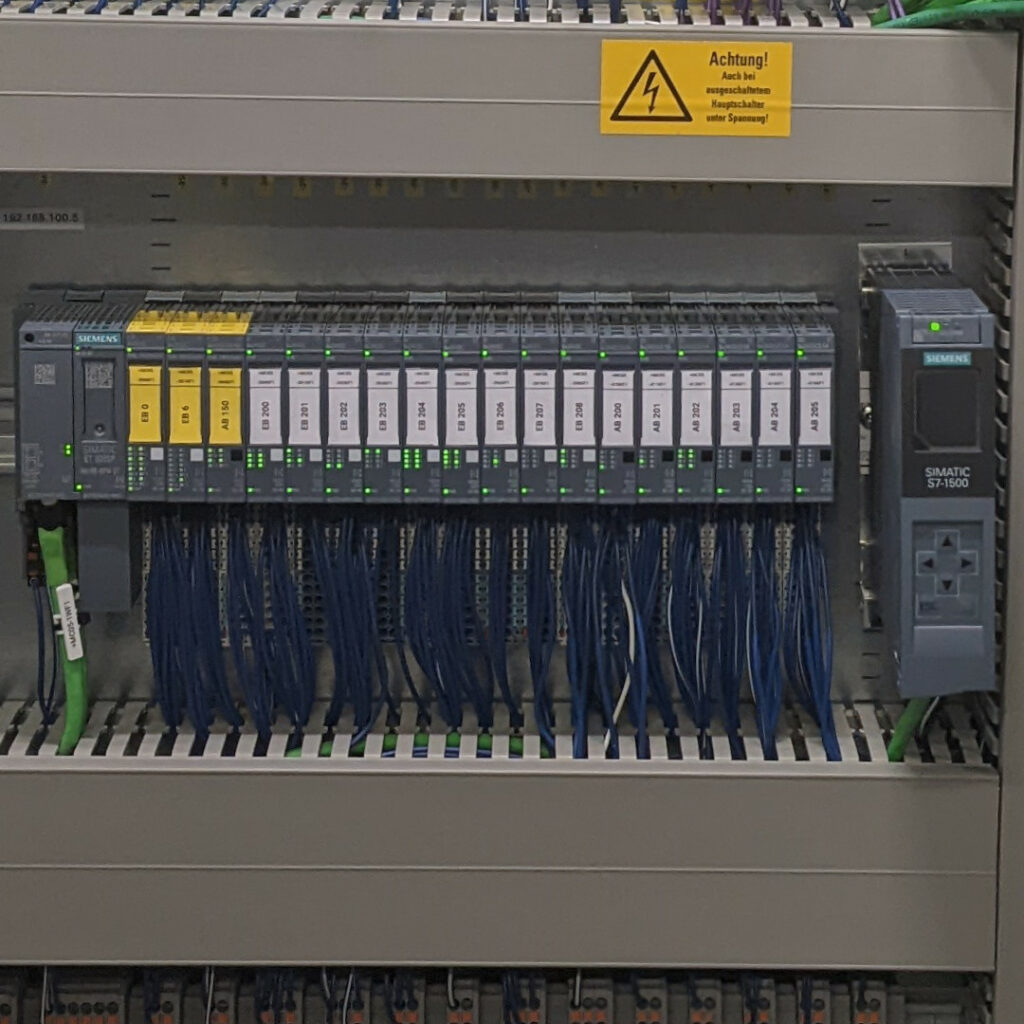

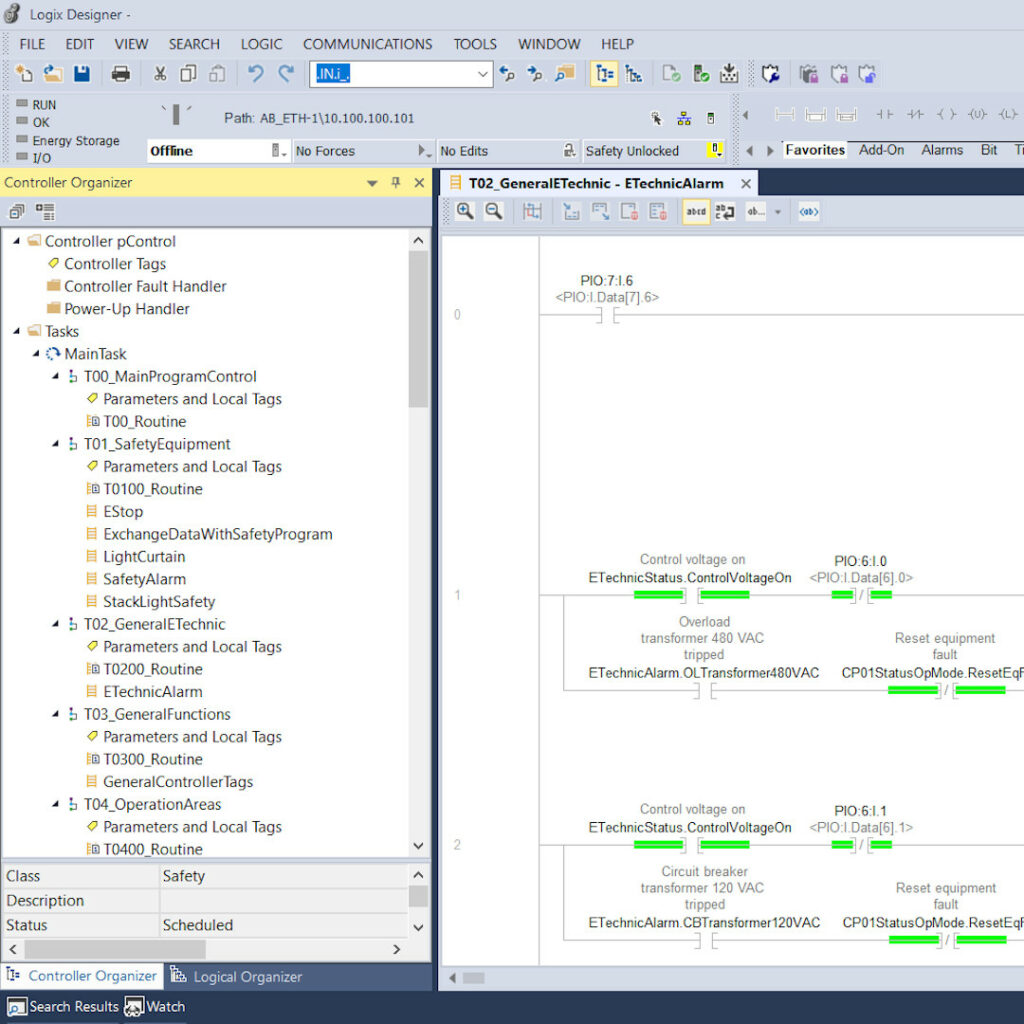

PLC software

We develop and program PLC programs for Siemens S7 and Allen-Bradley Control- and CompactLogix based on our pControl standard. Our software engineers have many years of experience and knowledge in the common programming languages according to IEC 61131-3 (e.g. KOP/LD, SCL/ST, FUP, AWL).

- Siemens TIA Portal and Simatic Manager for S7-300, S7-400, S7-1200, S7-1500

- Rockwell Studio 5000 or RSLogix5000 for Allen-Bradley ControlLogix and CompactLogix

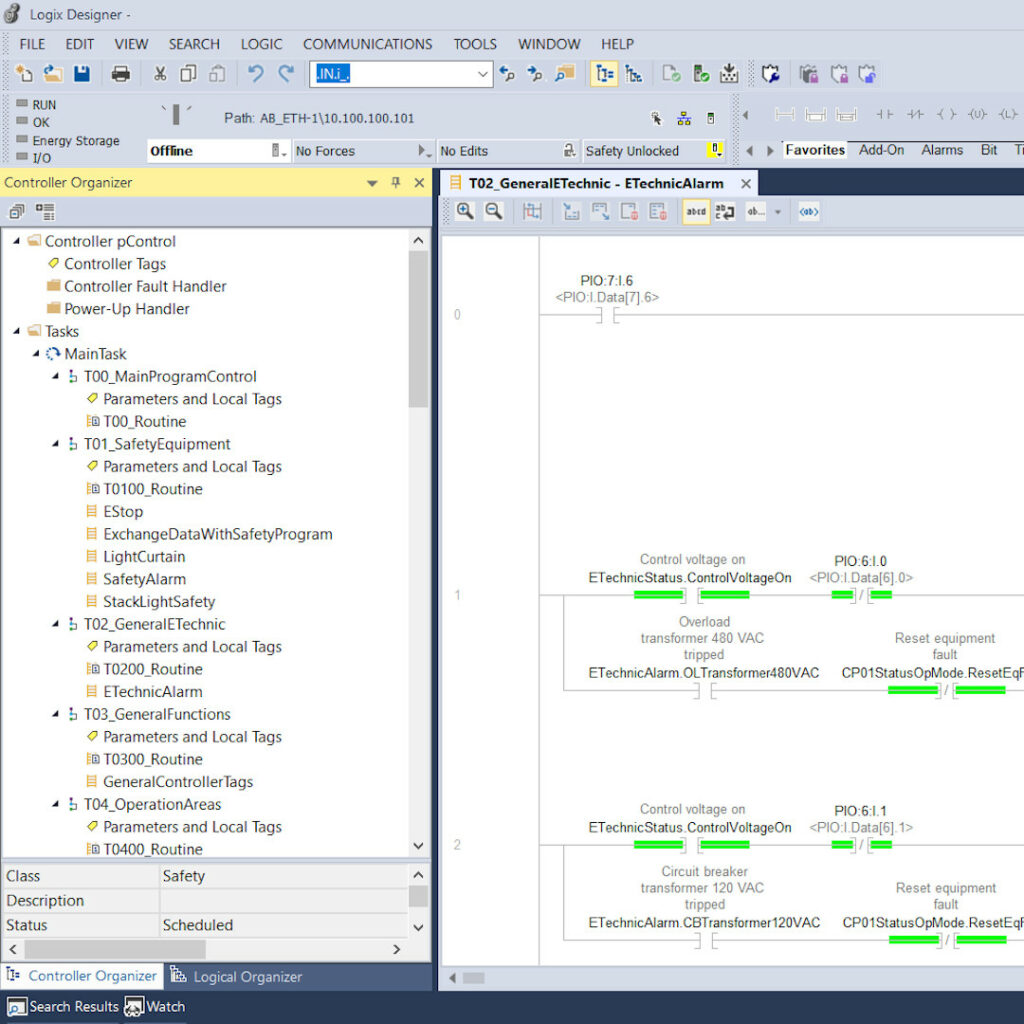

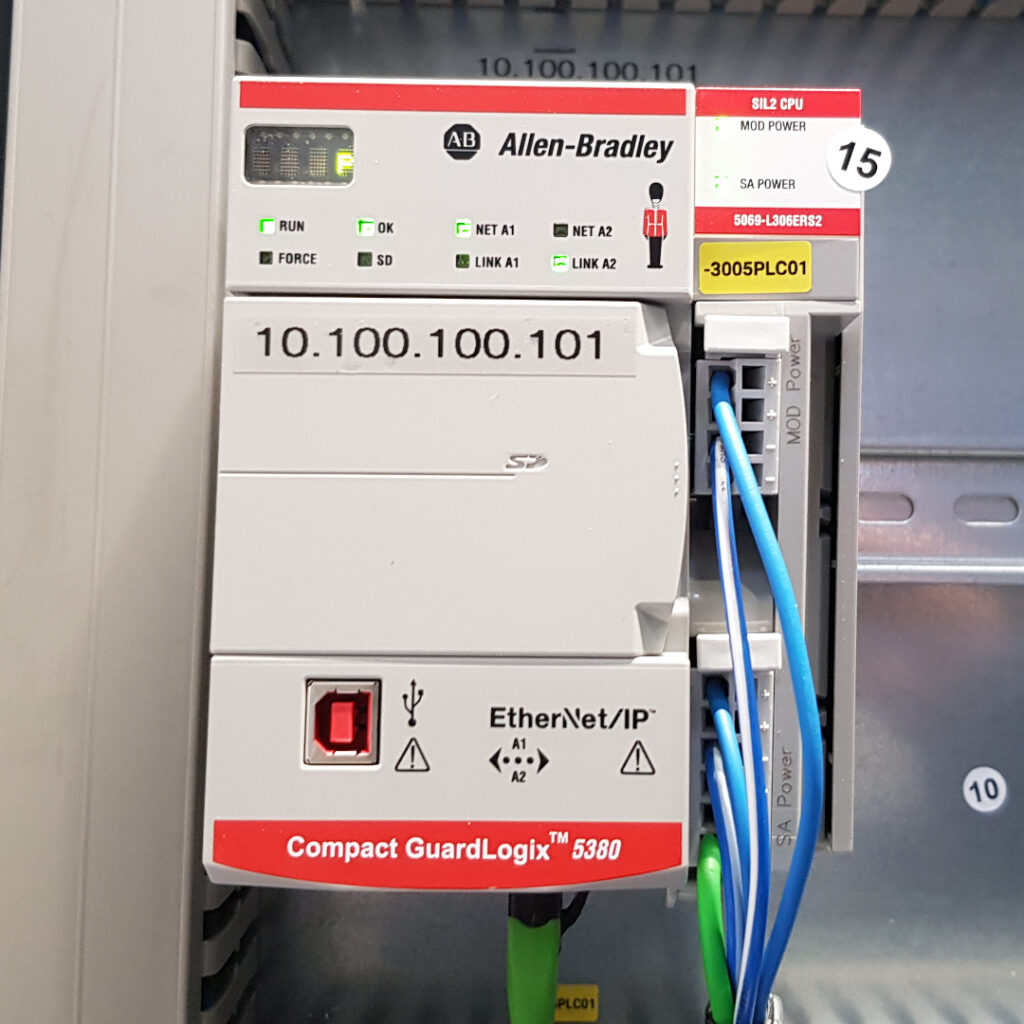

Safety program

Machines and systems must be safe. Today, safety functions that ensure this are implemented primarily by software in safety controllers. This offers many advantages over hardwired circuits. Furthermore, software-based safety functions open up new possibilities.

- Siemens Safety Integrated, Allen-Bradley GuardLogix

- configuration and parameterization of safe sensors (e.g. laser scanners, light curtains) and actuators (e.g. drive technology)

- new possibilities thanks to functional safety

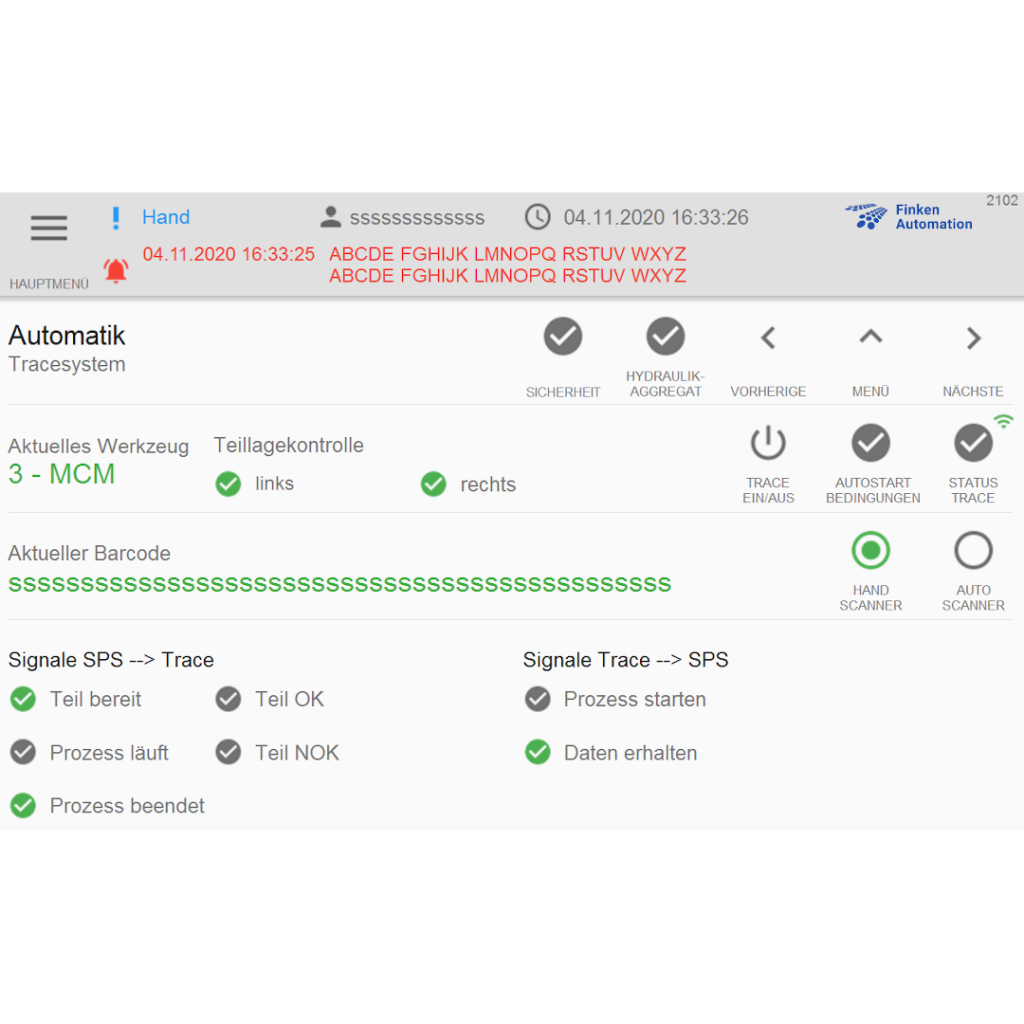

User interfaces

Intuitive and self-explanatory user interfaces as required for operator terminals or industrial computers with multiple users. One can always have the current status of the system in view and in case of technical breakdowns exactly the info that is required for troubleshooting. With our HMI pInterface, we offer our customers a modern operator interface for complex automation systems.

- Siemens TIA/WinCC Unified, Advanced oder Professional (auf Wunsch in Kombination mit WebNavigator)

- Rockwell FactoryTalk View Machine Edition (ME) or Site Edition (SE)

Real-time simulation and virtual commissioning

Die Maschine oder Anlage schon im Büro in Betrieb nehmen und Abläufe testen. Dies ist mit unserer Steuerungssoftware pControl möglich und wird dazu genutzt im Vorfeld das Steuerungsprogramm, sowie Materialfluss-/Lagerstrategien zu prüfen. Dank der in pControl integrierten Echtzeit-Simulation kann die virtual commissioning die Inbetriebnahme vor Ort oder Stillstandszeiten bei Retrofits erheblich verkürzen.

- firmly integrated in our pControl standard

- virtual commissioning thanks to real-time simulation

- testing processes and material flow/storage strategies in advance

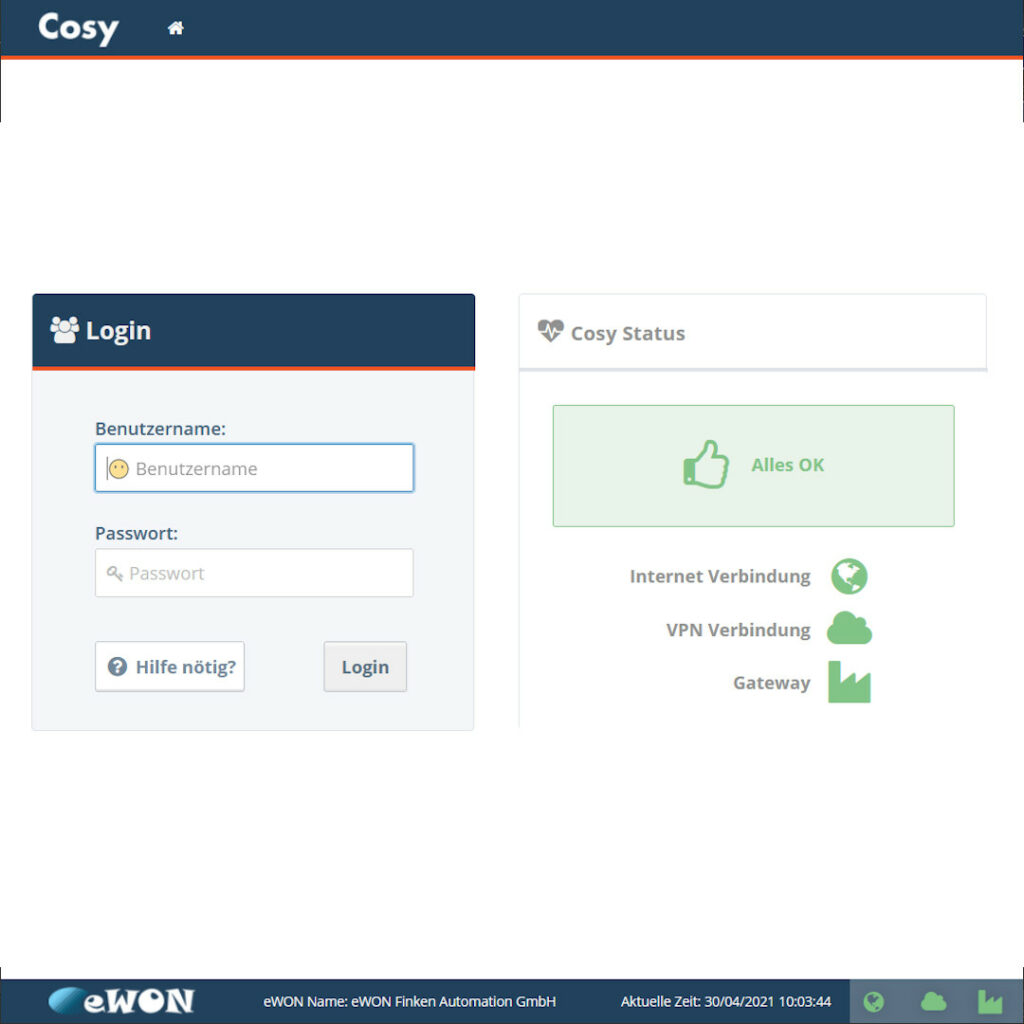

remote maintenance

Quick assistance in the event of a technical breakdown is possible thanks to the Internet. The machine is equipped with a secure VPN remote maintenance router for this purpose. When activated, this establishes a secure connection with our service team. Data traffic is protected from third-party access by encryption. And when remote maintenance is deactivated again after troubleshooting, the machine is disconnected from the Internet. A secure solution for emergencies.

- secure remote maintenance via the Internet

- wired or via mobile communications

- also as retrofit for existing systems

- 24/7 service hotline for quick support and assistance

Lassen Sie uns ins Gespräch kommen!

Vereinbaren Sie einen unverbindlichen Gesprächstermin, um über Ihre Herausforderungen und unsere Lösungen zu sprechen.